- The function of the commutator is to make alternating current into unidirectional.

- The direction of armature conductors are in one direction when conductors pass through N – poles and in opposite direction when they are under S – poles and vice versa.

- The reversal of current takes place when conductors pass out under influence of the N – poles and enter that of S – poles.

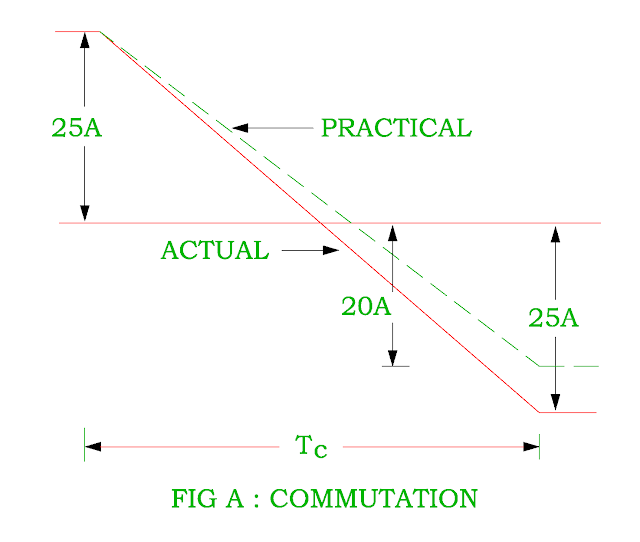

- The reversal of current takes places along magnetic neutral axis ( MNA ) or brush axis. The short – circuit period of coil is known as commutation period Tc.

- If the current reversal ( i.e. form + I to zero and then zero to – I ) is completed by end of commutation period, it is called as ideal commutation.

- If the current reversal is not completed by that time ( commutation time ), the sparking is produced between the adjacent commutator and brush.

Methods of Improving Commutation

The Following methods are used to improve commutation in DC Generators.

( A ) Emf commutation

- The sparking at the brushes or poor communication is due to the inability of the current in the short – circuit coil to reverse completely by the end of short circuit period or communication period.

- The main reason to delay quick reversal is due to self-induced emf in the armature coil. This self induced emf is known as reactance voltage.

- The self induced emf must be reduced in order to reduce sparking at brushes or to cancel this emf by means of any method.

- The interpoles or compoles are placed midway between main poles.

- The polarity of the interpoles is the same as that of main pole ahead in the direction of rotation in the case of generator.

- The armature winding is connected in series with interpole winding but the induced emf by the interpole is known as revesing emf because it cancel reactance voltage.

- The net reactance voltage neutralizes by the interpoles and sparkles operation can be achieved in this way.

( B ) Equalization connection

( C ) Resistance Commutation

- The low resistance copper brushes are replaced by high resistance carbon brushes in order to improve commutation in the DC machines.

- However they do not give a spark less commutation but they do help in obtaining it.

Advantages of Carbon Brushes

- They are self-lubricating.

- If sparking occurs, they would less damage the commutator as compared to copper brushes.

You may also like :

No comments:

Post a Comment