The classification of permanent magnet synchronous motor is done based

on induced emf in the it.

Brushless AC Motor

- When the waveform

of induced emf is sinusoidal, it is called as brushless AC Motor

Brushless DC Motor

- When the waveform

of induced emf is trapezoidal, it is called as brushless DC Motor.

Construction of BLDC motor

- The

configuration of BLDC motor is done on the basis of supply whether it is single

phase, two phase or three phase BLDC motor.

- Actually, the three phase BLDC

motor is used in the industries. The main parts of the BLDC motor are as below.

BLDC Motor: Stator

- The

construction of stator of BLDC motor is similar to that of three phase

induction motor stator but the stator winding distribution is different to that

of three phase induction motor.

- The stator winding is star connected and each

winding is connected through interconnection. According to interconnection of

the stator winding, the configuration of BLDC motor is

Sinusoidal BLDC Motor

- The

stator waveform of the sinusoidal BLDC motor is sinusoidal type.

- The torque

produced in the sinusoidal BLDC motor is smoother than that of trapezoidal BLDC

Motor but due to interconnection of stator winding its copper weight and cost

increases.

Trapezoidal BLDC Motor

- The

stator waveform of the trapezoidal BLDC motor is trapezoidal type.

- The voltage

waveform diagram of the three phase BLDC motor is shown in the Figure.

BLDC Motor: Rotor

- The

rotor of the BLDC motor is made of permanent magnet.

- The number of pair of

poles in the range of 2 to 8. The ferrite material is used to make permanent

magnet.

- The rotor material is selected based on necessary magnetic field

density in the rotor.

- The cost of ferrite material is less by considering

volume of rotor material but at the same time flux density in the rotor is also

less.

- The flux density of the ‘ rare

earth alloy ’ is higher than that of ferrite material for same volume of

material therefore for the same torque, the size of rotor resulting stator size

reduces when using rare earth ferrite material.

- The neodymium ( Nd ), samarium

cobalt ( Smco ), alloy of neodymium and Neodymium magnet ( NdFeB ) is used as

rare earth ferrite magnet material.

BLDC Motor: Hall sensor

- The

commutation process in the BLDC motor is done by electronic circuit.

- The stator

winding is energized in proper sequence in order to rotate BLDC Motor rotor.

- There

are three sensors placed at the non – driving end of the stator as show in the

figure.

- The function of the hall sensor is to check the position of rotor.

- The

hall sensors are placed at 120 degree to each other and commutation process is

done by them.

- When north or south pole of rotor passes closely to hall sensor,

the hall sensor generates low or high signal.

- This signal indicates north or

south pole of rotor passes through hall sensor.

- The power requires for hall

sensor may be provided form 4 Volt or 24 Volts.

- In order to make DC motor, brushless it is

considered as ‘inside out’.

- It means that the winding is placed on the stator

and rotor is made of permanent magnet.

- The reversal of current in the DC motor

is done by commutator and brushes whereas it is done by electronic switch in

the BLDC motor.

- When the response of hall sensor is low, electronic amplifier

or drive circuit works as commutator in the servo system.

Working of BLDC Motor

- The

DC supply to the BLDC motor is not given directly but it is given by reversing

through semiconductor switch for fixed rotor position.

- The torque in the BLDC

motor is produced when the stator magnetic field and magnetic field produced by

permanent magnet interact.

- The maximum torque is produced when two magnetic

fields are at 90 degrees to each other.

- The rotor moves and catch with stator

magnetic field to continuous rotation of rotor.

Torque – Speed Characteristics

- Figure

shows torque – speed characteristics of BLDC Motor.

- The BLDC can be loaded up

to rated torque during continuous operation. The torque remain constant upto

rated speed.

- When the BLDC motor run at 150% speed of rated speed, the torque

starts drooping.

- The BLDC motor is useful where frequent starts and stops and

frequent reversal of rotation with load is necessary.

Comparison between

conventional DC Motor and BLDC Motor

Commutation Sequence

- For

each commutation sequence, positive supply is given to one winding, negative

supply given to another winding and third winding is kept at de-energized

position.

- The rotor position is sensed through hall sensors placed on the

stator.

- The hall sensor changes its state ( low or high ) according to rotor

position. One hall sensor changes its state for every 60 degree of rotation of

rotor.

- It takes 6 steps to complete on electrical cycle. However, one

electrical cycle may not be equal to one mechanical revolution of rotor.

- One

electrical cycle is completed for each rotor pole pairs therefore the number of

electrical cycle is equal to number of pair of poles.

Relation between

electrical rotation and mechanical rotation

θe = (

P / 2 ) ( θm )

Where

θe =

Electrical rotation

P = Number of

poles

θm =

Mechanical rotation

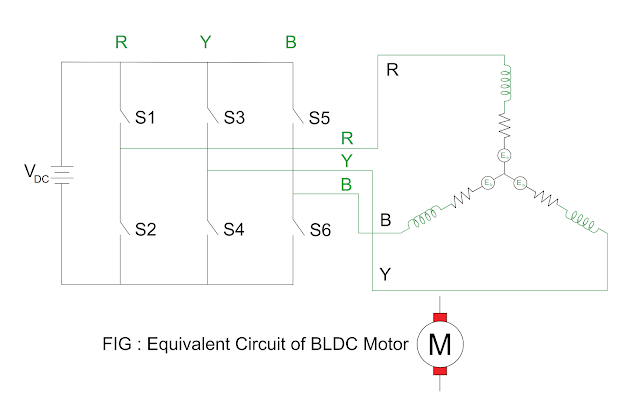

Equivalent Circuit

of BLDC Motor

- The

equivalent circuit of the BLDC motor is shown in the figure.

- The three-phase

supply to the stator winding is given through inverter.

- There are six

semiconductor switches in the three-phase inverter circuit, the switching of

semiconductor depends upon signal of hall sensors.

- The pulse width modulation

technique is used in order to switching semiconductor device.

- The frequency of

PWM is at least 10 times to that of maximum frequency of motor.

- The BJT,

MOSFET, IGBT or GTO is used as semiconductor switching device.

Switching Sequence in the BLDC Motor

- The

switching sequence for the position of hall sensor is show in the table.

- Hall

sensor – 1 shows high position whereas hall sensor – 0 shows low position.

- Figure shows position of hall sensors and current passes through coil R, coil Y

and coil B with reference to hall sensors position.

- The commutation sequence of semiconductor for six

position of hall sensor is shown in the figure.

|

Sr. No

|

Hall Sensors

|

Phase

|

Semiconductor

Switches “Switched ON”

|

|

1

|

101

|

R ( + ) – Y ( -

)

|

S1 & S4

|

|

2

|

100

|

R ( + ) – B ( -

)

|

S1 & S6

|

|

3

|

110

|

Y ( + ) – B ( -

)

|

S3 & S6

|

|

4

|

010

|

R ( - ) – Y ( +

)

|

S2 & S3

|

|

5

|

011

|

R ( - ) – B ( +

)

|

S2 & S5

|

|

6

|

001

|

Y ( - ) – B ( +

)

|

S4 & S5

|

( 1 ) The position of hall sensor H1H2H3 – 101 or electrical 60 degree, phase R gets positive supply, phase Y gets negative supply and phase B is kept in deenergized condition. This will result in semiconductor switch S1 and S4 is switched on.

( 2 ) Similarly, the position of hall sensor H1H2H3 – 100 or electrical 120 degree, phase R gets positive supply, phase B gets negative supply and phase Y is kept in deenergized condition. This will result in semiconductor switch S1 and S6 is switched on.

Applications

& Features of BLDC Motor

Applications

- Constant load: Fan,

blower, pump

- Variable load: Compressor,

dryer, washers, fuel control, electronic steering control, engine control,

robotic arm control, gyroscope control etc.

- Position control: Computer

numeric control ( CNC ) machine, process control, conveyor control

Features

- High efficiency

- High power factor

- Silent operation

- Compact

- Reliability

- Low maintenance