Capacitor Start

– Induction run Single Phase Motor

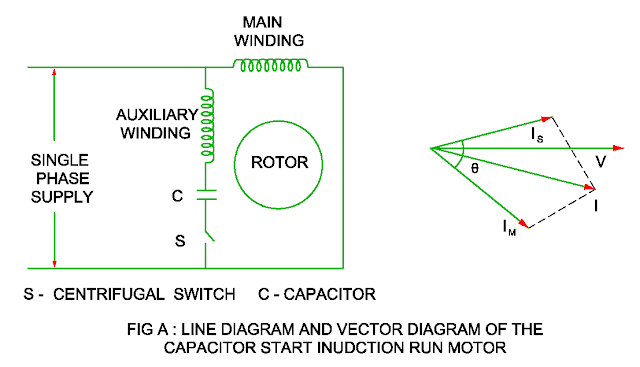

- The phase difference between main winding and starting winding is achieved by introducing an electrolyte capacitor is in series with starting winding.

- The capacitor is electrolyte type. When the speed of the motor is increased 70 to 80% of full load speed, the centrifugal switch open and starting winding is cut out.

Vector

diagram

- As the capacitor is in series with starting winding, its vector IS leads supply by some angle.

- The current vector IM lags the supply voltage by some angle ( < 900 ) due to high inductance of the main winding.

- The angle between current vector IS and IM is in the range of 800 to 900 which is nearly 300 in the case of Split phase motor.

Starting

torque

- The starting torque is directly proportional sine of angle between starting current and main current.

T a

( Sin θ )

- The starting torque in the capacitor start – induction run motor is about 3.5 to 4 times that of full load torque.

Advantage of Centrifugal switch over Magnetic switch

- It is not

affected by the line voltage

- More reliable

- Low cost

Electrolyte

Capacitor

- It is formed by

winding two sheets of etched aluminum foil and separated by two layers of

insulating layer in the shape of cylindrical.

- This whole unit is impregnated

with an electrolyte of ethylene glycol.

- An anodic film is produced on each foil

by the electro – chemical action.

- The voltage rating of the capacitor should

not necessary be same as that of motor rating.

- The power factor of the such

capacitor is in the range of 6 to 8 %.

Speed Regulation

- The speed of the

motor varies 10% to 100% from no load to full load

Rating

- It is available

in the range of 1/6 HP to 3 HP.

Application

- Compressors

- Elevators

- Conveyors

You may also like :

Neutral Shifting in the Transformer

Auto transformer working and Saving in Copper

Armature Reaction in the DC Generator

Compare Power Transformer - Distribution

Transformer

Function of Dummy coils

Auto transformer working and Saving in Copper

Armature Reaction in the DC Generator

Compare Power Transformer - Distribution

Transformer

Function of Dummy coils

No comments:

Post a Comment